Shri Sadhi Krupa Polysacks: Woven Fabric Manufacturer

We have been a credible name and the top choice of our clients since the inception of the company. As a leading woven fabric manufacturer, we specialize in the manufacturing, exporting and supplying of HDPE/PP woven fabric to our clients.

Years ago, we looked at HDPE/PP woven fabric and bags/sacks from the well-known brand Tool Asian Polysacks Pvt. Ltd.

We are well-known as the leading manufacturer, exporter, and supplier of HDPE/PP woven fabric and bags/sacks. Shri Sadhi Krupa Polysacks Pvt. Ltd. is recognized as a one-stop production hub for woven packaging and technical textiles.

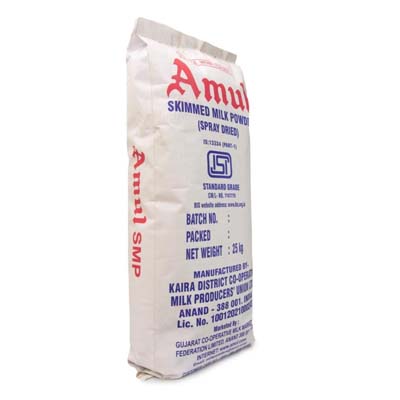

We are providing excellent quality packaging solutions as per the specifications, dimensions, and weights of our customers. Our woven fabric & PP woven bag products are flexible, high-strength, durable, and widely used in fertilizer, cement, sand, food grains, sugar, cattle feed, fish meal, pulses, spices, dates, agro products, minerals, resin, polymers, rubber, etc.

What is Woven Fabric? - A Complete Guide

A cloth formed by weaving is known as woven fabric. Woven fabric means fabrics composed of two sets of yarns. The one set of yarns, called the warp, runs along the length of the fabric. The other set of yarns, called the fill or weft, is perpendicular to the warp.

Woven fabrics are held together by weaving the warp and the fill yarns over and under each other. The weft yarns move horizontally, while the warp yarns move vertically down the loom. There are different types of woven fabric, such as plain weave, twill weave, and satin weave.

Plain weave is formed by alternating the weft and warp yarns evenly, and twill has the yarns arranged to form diagonal lines that give the fabric a slightly twisted or slanted view, creating a slight texture. Satin weave has a different arrangement of yarns and gives the fabric a very smooth surface finish, creating the desired shiny and luxurious fabric.

Reason For Using The PP Woven For Packaging Use

Easy to produce, Assemble, and an Economic Material

Resistant to most Alkalis, Acids, Organic Solvents, and Degreasing Agents

High operational temperatures with a melting point of 167°C

Non-staining and Easy to Maintain

PP Woven are Non-toxic in Nature

Very easy to clean and Antibacterial in Nature

100% Reusable and Highly Durable

Breathable or Waterproof with a Laminated Film

Excellent Resistance to Stress and High Resistance to Cracking

Feature of High Melt Index with Low Density

Infrastructure

We have state-of-the-art and world-class infrastructure at our very large facility, where we are fully stocked with everything we need to honor our bulk client orders on time, as expected.

Our operations follow a predesignated path, which includes manufacturing, quality assurance, R&D, and warehousing, with all four departments working together to produce high-quality polyethylene and polypropylene bags for packaging. Our plant is fully autonomous and runs high-performance automated GCL cutting and stitching machines to give you the highest productivity.

We are backed by a team of qualified technical and non-technical staff with vast experience in the field. We even have an in-house laboratory equipped with the most advanced testing facilities for HDPE bags and HDPE sacks.

We ensure product quality and reliability with advanced testing equipment and robust manufacturing facilities, equipped to produce PP/HDPE woven fabric sacks.

Woven Fabric Manufacturing Process

Extrusion

Extrusion is the main process of the whole woven polymer processing value chain. These extrusion machines are equipped with the best-in-class equipment. Our extrusion lines have all the necessary attachments, like melt pressure pumps, static mixers, capacitance gauging of film, automatic dosing mixing direct silo-based feeding, annealing, and quenching for low shrinkage conditioning.

Extrusion Coating

This extrusion coating process is the coating of a molten web of synthetic resin against a substrate material. It is known as a multipurpose coating technique used for the economic application of various plastics, notably polyethylene, corrugated fiberboard, paper, and aluminium foils.

Finishing

The finishing section is designed for smooth workflow and a neat and clean atmosphere and is prepared with cleaning blowers. The quick, trained, and committed workforce works as a team to distribute steady, quality products.

Webbing

Webbing is known as a strong fabric woven as a flat strip or tube of varying width and fibers, which is often used in place of rope.

Twisting and Filler Cords

We are furnished with an in-house facility for fibrillating and twisting our own stitching yarn to provide our customers with totally customized solutions.

Weaving

Weaving is the main process of making fabric or cloth. Weaving is when two distinct sets of yarns called the warp and the filling, or weft, are interlaced with each other to form a fabric.

Printing Section

Printing section is one kind of dyeing. Printing is carried out after pre-treatment of fabric or after dyeing of the fabric. This process is known for applying the color to fabric in definite patterns or designs.